Meeting the Challenges of the Oil and Gas Industry

FLIR SOLUTIONS FOR OIL & GAS

Oil and Gas producers have to take on a range of responsibilities, from detecting leaks to meeting environmental regulations, maintaining site security and system integrity. How companies address these issues often depends upon whether they are upstream, midstream, or downstream producers.

Read on to learn about Oil and Gas applications and the FLIR products that can help inspectors, managers, and technicians solve problems quickly and avoid expensive shutdowns.

![]()

Explore Your Oil & Gas APPLICATION

EXTRACTION AND PRODUCTION

Whether it involves offshore drilling, hydraulic fracturing, or a production well, natural gas producers need the right tools to avoid product loss and safety hazards caused by unseen leaks.

Transmission and Transportation

Regular preventative maintenance helps oil & gas producers avoid fugitive emissions, verify tank levels, and ensure transmission and transportation equipment is running smoothly.

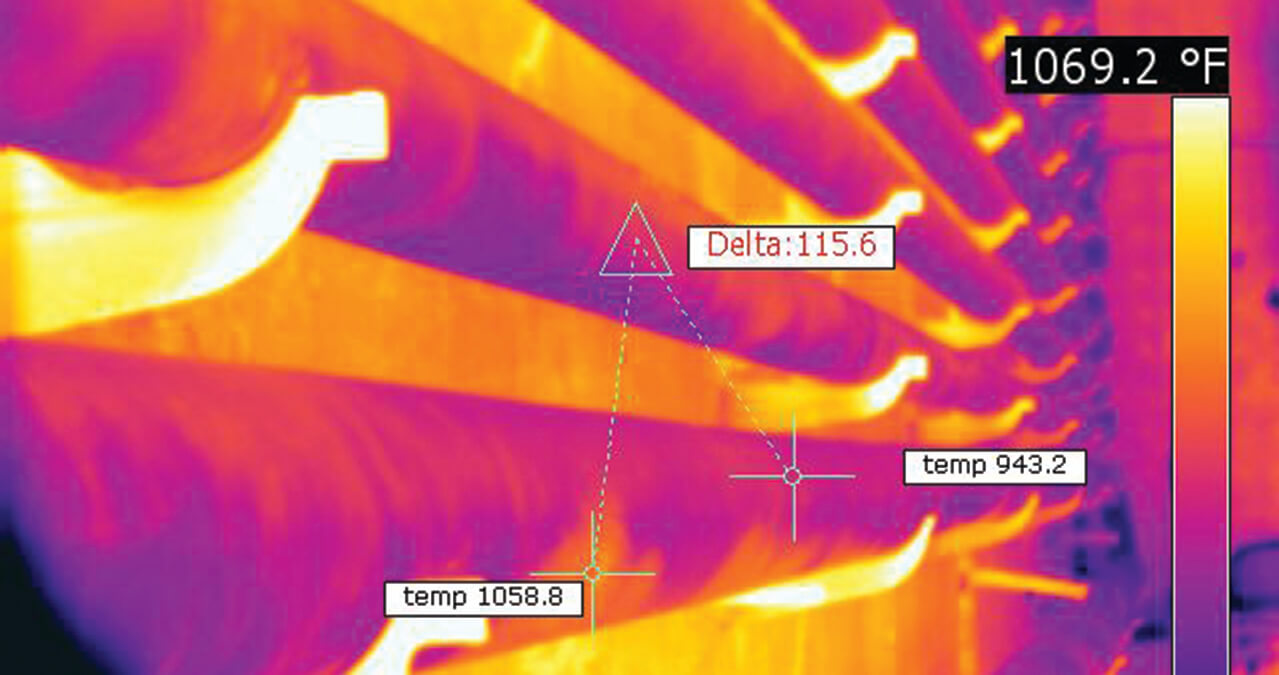

PROCESSING AND REFINING

Processing and refining present unique challenges—from fired furnace damage to critical vessel failure. It's up to service providers to catch potential failures and get them fixed before they turn critical.

FLIR allows us to give oil and gas clients visual evidence of profit loss.

Matthew Grissom, Optical Gas Imager, Environmental Compliance Associates, Inc

TechValidate. TVID: 566-FF8-445

Innovation in Action

View All

How Optical Gas Imaging Benefits a Low-Carbon Economy and Corporate ESG Reporting

Read the Story

Cutting Costs, Product Loss, and Downtime

FLIR optical gas imaging (OGI) cameras are used throughout the Oil and Gas industry to detect methane and other hydrocarbon emissions from the extraction, transmission, and processing of petroleum and natural gas. These cameras visualize hundreds of invisible gases, allowing inspectors, engineers, and maintenance crews to identify leaks safely without having to shut down critical systems.

Inspect Safely in Explosive Environments

The FLIR Cx5 is certified for use in many explosive environments, so you no longer have to acquire hot work permits due to gas, vapor, and dust. With the Cx5, T-Class surveys can be quick and easy. Featuring FLIR MSX® (Multi-Spectral Dynamic Imaging) and 1-Touch Level/Span, the Cx5 can help you identify potential problems quickly to improve plant performance. Built-in FLIR Ignite™ cloud service allows you to directly transfer, store, and backup images, so they're always accessible when you need them.

Webinars for Oil and Gas

View All

Infrared Thermography Training Resources

Infrared Thermography Training Resources

Sign up for scheduled infrared thermography training courses offered through the Infrared Training Center (ITC).

Learn more

Do you have a large group that requires thermography training? The ITC will organize an onsite training course.

Request training