Thermal Process Monitoring for Thermoforming

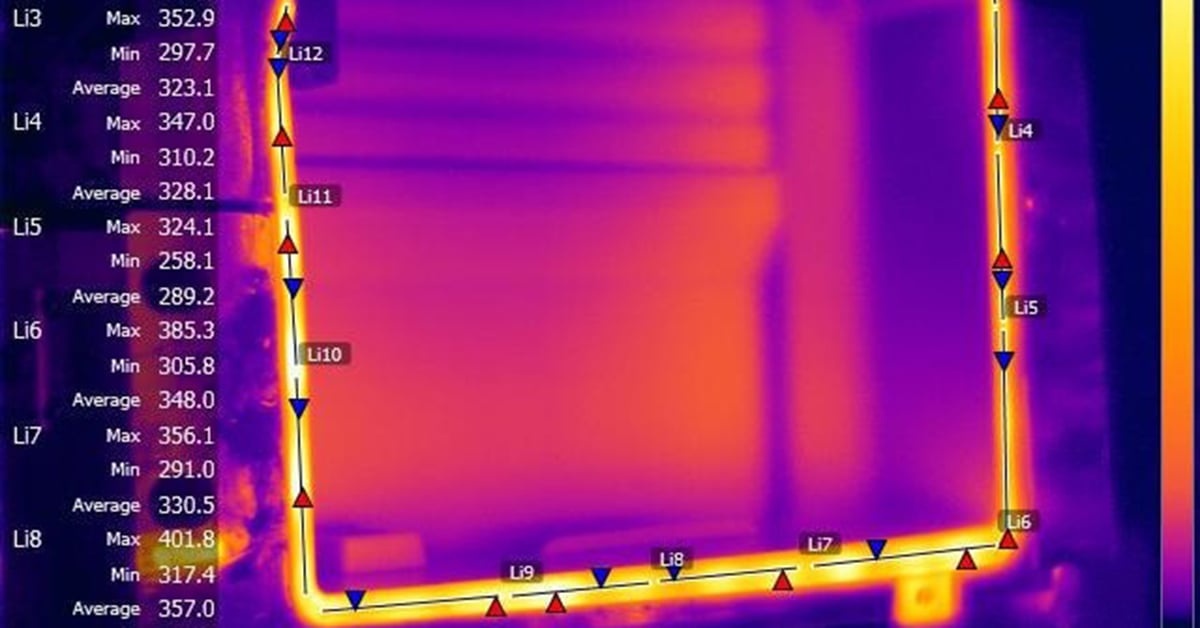

Do you validate and optimize your thermoforming, vacuum forming or compression molding processes with closed loop process control capabilities? Thermal Machine Vision Solutions are the #1 solution for thermoformers being used today. By thermally inspecting parts after the heating cycle, analysis can be used to validate the heating process. Feedback is provided to your PLC, enabling immediate corrective actions to your heating zones. Inspection and control of heated components is key to producing quality parts, increasing throughput, reducing scrap rates, and validating product control.

Learn:

- About solutions for validating heat process control

- How to reduce startup time and scrap

- How to add a close-loop oven zone control

- About processing bottlenecks and root problems

Presenters:

CHRIS LEMMONS, Emitted Energy Corporation

Experienced Program Manager with an MBA and Bachelor's degree in Engineering management. Chris has a demonstrated history of working in the automotive industry.

ADAM BIERL, Emitted Energy Corporation

Experienced Technical Sales and Account Manager within Manufacturing/Automation Industry specializing in Infrared Technologies; ITC Level II Certified Thermographer.

ABOUT EMITTED ENERGY CORPORATION

Emitted Energy is an industrial solutions provider specializing in the application of infrared technology. We improve our customers' bottom line by providing robust, turnkey solutions, high quality products, and comprehensive services using infrared machine vision and infrared heating elements.