Improve Condition Monitoring with Thermal and Acoustic Cameras

The global energy crisis has placed an incredible financial strain upon businesses throughout the UK and Europe. The recent Business Energy Tracker report from Npower Business Solutions shows that 80% of organisations consider energy to be their biggest threat.

Unable to control the rising cost of energy, businesses are instead looking to reduce their operating expenses. By not only resolving active energy leaks, but also proactively identifying potential faults before they become major problems, preventative maintenance can be undertaken to avoid wasteful energy loss and costly downtime. This also helps to reduce a facility’s carbon footprint and meet climate change goals.

But with so many competing condition monitoring priorities and an already overstretched team, it’s challenging to catch these issues early and create a budget-friendly maintenance schedule. Businesses often lack the tools to detect, visualise and report problems quickly, particularly when many of the warning signs are invisible.

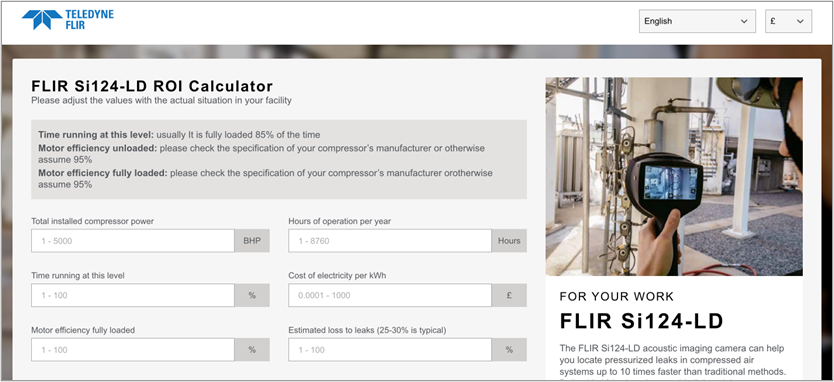

To assist businesses in cutting energy consumption, Teledyne FLIR designs and manufactures thermal and acoustic imaging cameras specifically for business use, supported by our exceptional total solution ecosystem of cloud-based backup and reporting software. This intelligent sensing technology highlights hidden energy loss, industrial faults, system leaks and more to improve efficiency and reduce energy costs. Our products consistently outperform other brands in accuracy and precision testing, and their range of functionality is suitable across a wide range of industries, business sizes and requirements. Teledyne FLIR has also developed a handy ROI calculator which demonstrates how much the average business could stand to save by investing in our technology.

Image: FLIR’s Return on Investment Calculator for businesses

Take, for example, a compressed air leak from a small hole of just 1.5 millimetres on a network of compressed air at seven bars of pressure. Two years ago, with a price of €0.07 per kilowatt hour, that alone would have cost a company roughly €1500 (£1300), assuming an operating time of 6000 hours per year.

Thermal Imaging Cameras from Teledyne FLIR

Thermal imaging cameras can be used to assess motors, pumps, electrical connections, and other industrial equipment for invisible faults. These can then be maintained or repaired before they cause major energy loss or equipment failure. Our thermal cameras are also useful in office environments for detecting areas of poor insulation and heat loss, which also contribute to expensive energy costs.

FLIR Ex Series – Perfect for on-the-spot condition monitoring, these professional thermal imaging cameras are suitable for SMEs who conduct monthly, bi-monthly, or infrequent inspections. The series includes standard and extended temperature ranges to cover any business application, and their Wi-Fi connectivity allows for simple and convenient image transfer.

FLIR Exx Series – Exceptional thermal imaging for predictive maintenance, able to detect and troubleshoot problems before they cause serious damage. With on-board inspection routing and FLIR Thermal Studio integration, this series speeds up surveys and simplifies reporting for larger industrial or manufacturing settings. That means your team can spend more time inspecting and less time building reports. The broad temperature range allows for use in metalworking or glass manufacturing, and changeable lens options enable condition monitoring over long distances for equipment at heights.

Acoustic Imaging Cameras from Teledyne FLIR

Acoustic imaging cameras are used to locate leaks in compressed air and gas systems, and vacuum systems. This makes them an excellent choice for almost every manufacturing or production operation. Our equipment also comes with a built-in severity indicator that shows yearly leak rate and cost in GBP or Euros, helping you prioritise areas of high savings.

FLIR Si124 – This acoustic imaging camera displays ultrasonic information visually and transposes it in real time over a digital camera image. Doing so allows accurate identification of pressurised leaks, or partial discharge from high-voltage electrical systems.

Explore the Industrial Applications of Intelligent Sensing Technology

The sheer variety of industrial applications can make it tough to visualise how thermal and acoustic imaging cameras could support your business specifically. Read our case studies, application stories, use case scenarios and other articles to find out more, and use our ROI calculator to discover how much your business could save with us.