FLIR thermal imaging cameras improve the credibility and efficiency of underground snow-melting systems

One thermal image clearly demonstrating a hidden problem can sometimes be more persuasive than a long-winded, data-filled report. For companies that install and maintain underground snow-melting systems, FLIR thermal imaging cameras are proving their worth for temperature monitoring and in post-operational maintenance tasks.

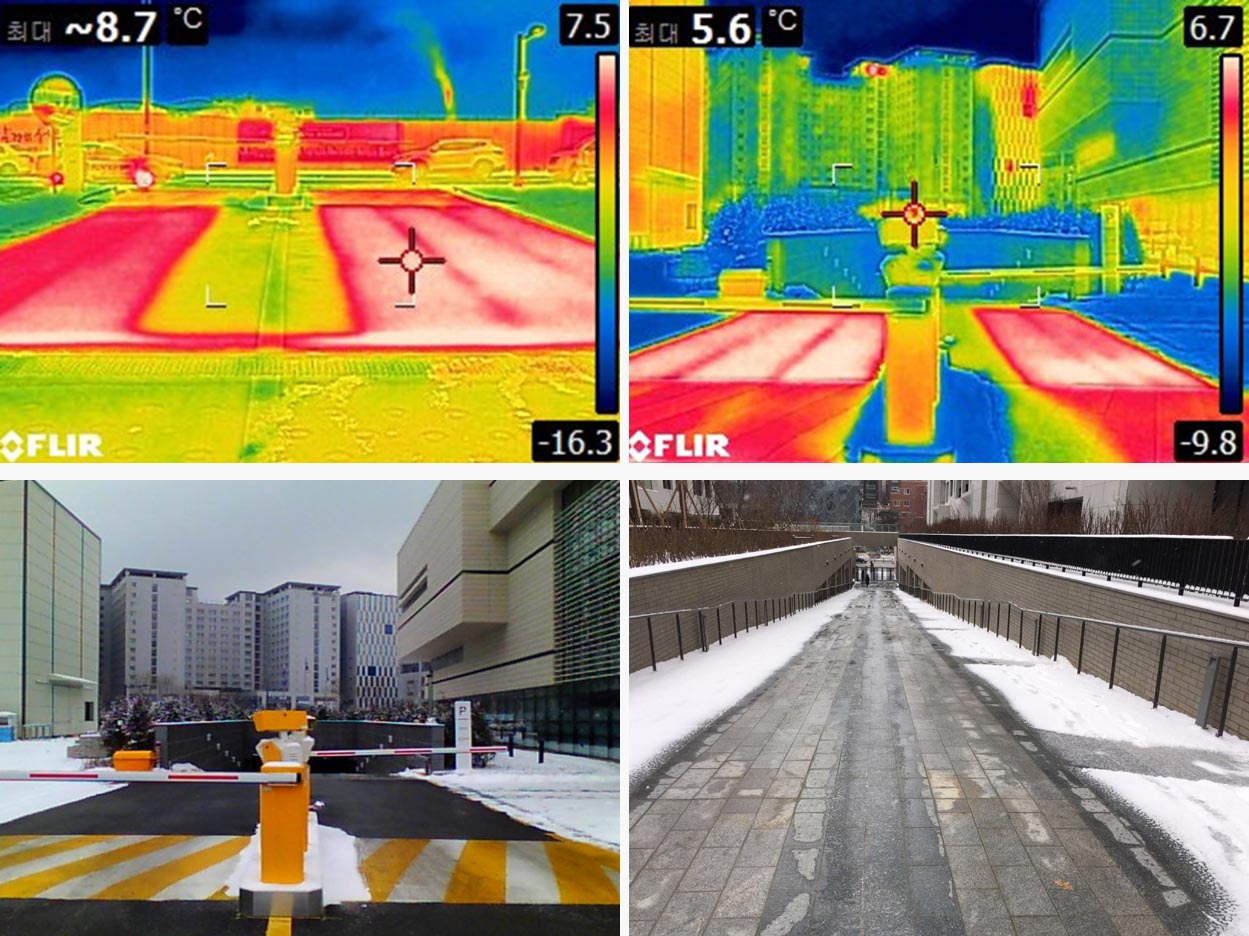

Winter snow can be a welcome sight for children. For most drivers, however, snow is bad news that can lead to traffic jams and traffic accidents. Of particular concern is black ice, which forms when the snow melts during warmer daytime hours freezes over again when the temperature drops in the evening. Snow or ice on steep slopes, curved roads, entrances and exits of tunnels, and other points where underground parking structures meet the road require added attention compared to other road surfaces.

The FLIR E5 thermal imaging camera is a key piece of equipment that improves the credibility, reliability, and efficiency of tasks involving snow-melting systems from their installation to supervision, and maintenance.

Snow-melting systems

In recent years, many governments have introduced snow-melting systems in order to mitigate the risk of accidents caused by snowfall and frozen ice in winter. These underground systems typically feature electrically heated wires and sensors embedded up to 150 mm (6 in.) below the road surface. When snow piles up or ice covers the road, the sensors automatically detect the temperature and humidity, supply power to the heated wires, and generate heat to melt the snow or ice. While some municipal governments still spray calcium chloride to clear snow or ice from roads, this can lead to corrosion; there also is some controversy regarding potential contamination of soil and water. Since snow-melting systems can eliminate this concern, they are rising in popularity not only for motorways, but also sidewalks for pedestrians and access points leading in and out of various buildings.

Using thermal imaging cameras for system maintenance

Since 2007, Namdong Engineering & One has installed more than 500 snow-melting systems in apartments, office buildings, hospitals, hotels, resorts, department stores, shopping malls, central government and local government offices, as well as military facilities. In 2014, the company added the FLIR E5 thermal imaging camera to its protocols for system installation and post-installation inspection and maintenance.

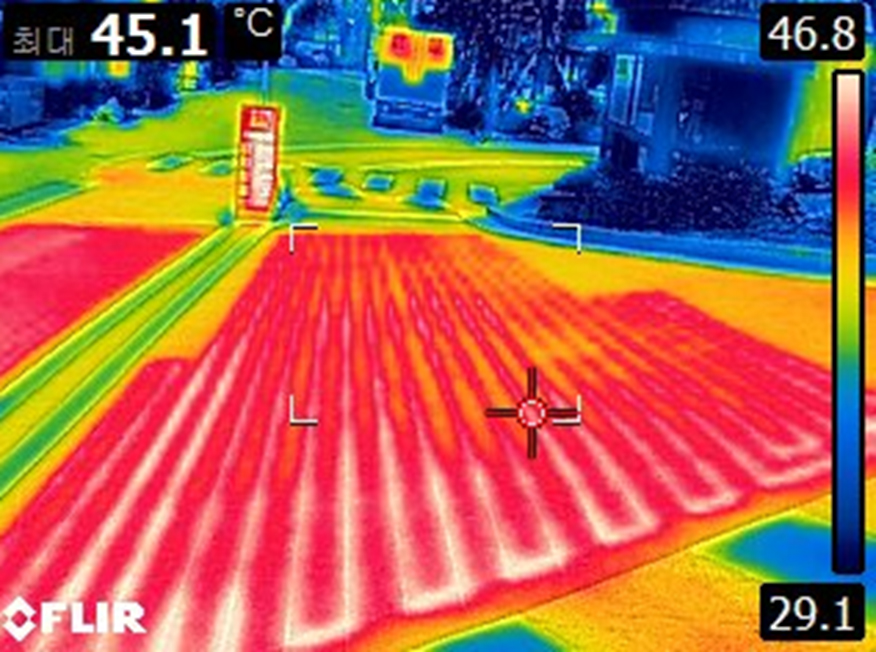

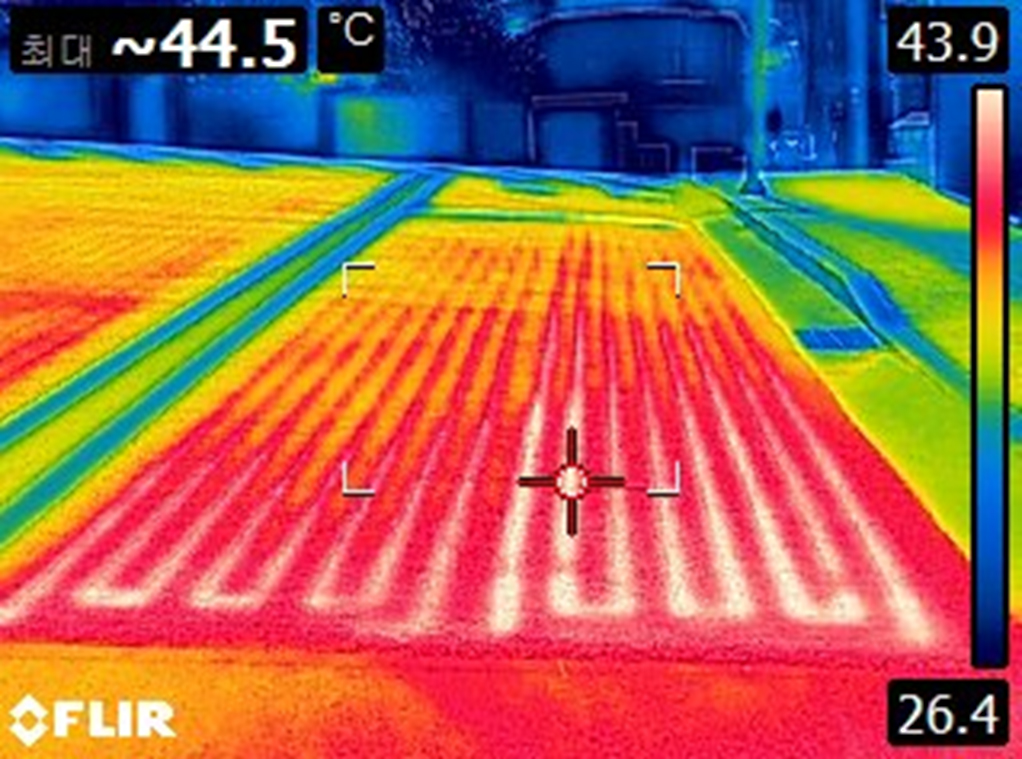

As Kim Byeong-sam, CEO of Namdong Engineering & One, explains, “Snow-melting systems are difficult to install or inspect with the naked eye since they involve embedding heated wires in the ground. That makes thermal imaging cameras perfect for checking snow-melting systems with clients and installation supervisors to determine whether the heated wires are operating normally. These cameras visualize and display the minimum and maximum temperatures using different colors, making the images very easy to interpret.”

Kim explains that, from a credibility standpoint, it is much more effective to let clients and supervisors check the operational status of underground equipment themselves with a thermal imager in the field rather than explaining the results in words. He adds, “Using a thermal imaging camera is much more convenient when performing maintenance tasks after snow-melting systems have been installed. If a problem occurs with the heated wires, a thermal imaging camera will display it in a different color compared to fully operational wires. That helps us check out and respond to the problem much swifter than without a thermal imaging camera.”

Visual image (above) and thermal image of a road with an embedded snow-melting system.

FLIR E5 thermal imaging camera

FLIR E5 is a popular thermal imaging camera widely used for the installation and inspection of electrical facilities as well as for preventive maintenance. In addition to providing both thermal and visual imagery, FLIR E5 uses FLIR’s patented MSX® technology to display details such as numbers and labels as well as the outlines of objects on thermal images clearly. It has a resolution of 10,800 pixels and a measurable temperature range from -20°C to 250°C (-4°F to 482°F). Thanks to an intuitive point-and-shoot mechanism, E5 is extremely easy to use and robust enough to pass a 2 m (6.5 ft) drop test. The camera features a center spot meter function for measuring temperatures and provides an area box tool for automatic maximum/minimum temperature readings. The E5 can be used for up to four hours on one battery charge; the removable lithium-ion battery can be recharged within two hours using an optional charging cradle or 2.5 hours while in the main camera unit.

Download the full application note and learn more at flir.com/ex-series