Leveraging Acoustic Imaging for Proactive Maintenance in Conveyor Systems

In industrial settings the early detection of machinery faults is crucial for preventing costly breakdowns and ensuring the smooth operation of equipment. A proactive approach using an acoustic camera proved instrumental in identifying and addressing critical bearing faults at a metalworking facility.

Conveyor systems play a crucial role in various stages of manufacturing processes across industries, helping to achieve a more streamlined, automated, and efficient production flow, ultimately improving productivity and product quality. However, constant wear and tear can cause the conveyor system and its components, such as bearings and idlers, to deteriorate. If not detected and addressed in time, this deterioration can result in faults, reducing system efficiency, increasing energy consumption, and, worst of all, causing unplanned and costly downtime. The traditional maintenance approach relies heavily on routine inspections and reactive responses to reported issues, which may not always capture hidden faults leaving room for unexpected breakdowns and costly repairs.

Uncovering Critical Bearing Faults for Proactive Maintenance

The key to overcoming these challenges lies in adopting advanced fault detection technology, such as acoustic imaging, that allows for early-stage identification of critical issues. As a recent inspection performed at a metalworking facility indicates, the FLIR Si2 acoustic camera equipped with market-leading technology was able to identify critical faults in machinery components. Not only did the camera findings confirm suspicions about known issues within the conveyor system, but it also uncovered a significant fault that led to a drive coupling failure between an electric motor and pump just a few days after the inspection. The metalworking company representatives were especially impressed with the snapshots taken of the detected faults with the acoustic camera, which they found extremely helpful and easy to interpret. Utilizing the decision support provided by the FLIR Si2 acoustic camera, a plan was immediately put in place to replace various chains and bearings.

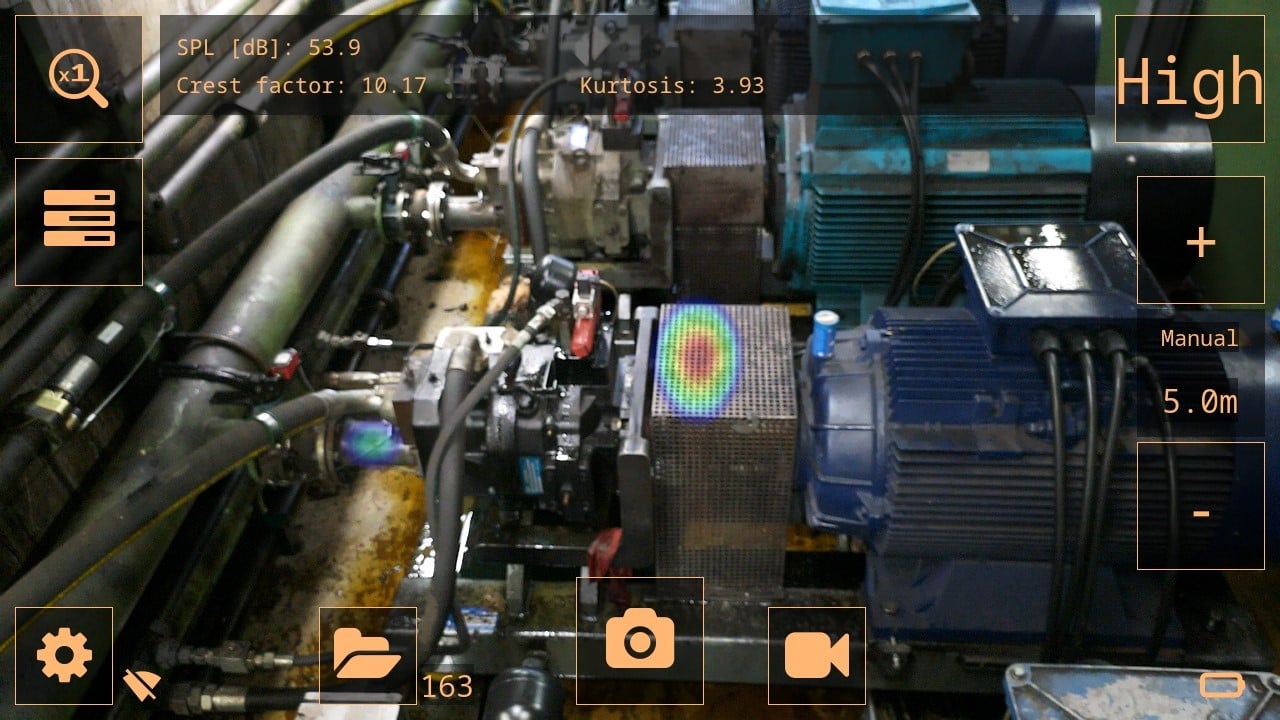

Snapshot of a mechanical fault taken with the FLIR Si2 Acoustic Imager: A high SPL (Sound Pressure Level), crest factor and kurtosis are often signs of potential issues with bearings. For most reliable results it is recommended to always compare the readings to healthy bearings of the same type, measured from a similar distance.

A Streamlined Acoustic Solution for Mechanical Fault Detection

One of the key benefits of using acoustic imaging for advanced fault detection is that it allows for proactive maintenance rather than reactive responses. Identifying potential issues before they escalate ensures a more efficient and cost-effective approach to equipment upkeep. This also leads to another benefit; cost savings. By addressing faults at an early stage, organizations can significantly reduce the costs associated with major repairs and unexpected downtime. In the highlighted case, the detection of a drive coupling failure prevented further damage to surrounding components by enabling proactive corrective measures to be taken.

The results of the mechanical fault inspection at the metalworking facility highlight the effectiveness of acoustic imaging in industrial maintenance. By proactively identifying and addressing mechanical faults by embracing advanced fault detection technology, organizations can not only save costs but also enhance the reliability and safety of their operations.

Benefits of Using Acoustic Imaging for Mechanical Fault Detection

- Allows for quick detection and measurement of bearing and other mechanical issues that can lead to costly production disruption or safety hazards.

- Ensures operational continuity by preventing unplanned downtime in critical machinery, such as pneumatic equipment and conveyor systems.

- Scans large areas and pinpoints critical problems accurately, even in noisy industrial environments.

- Provides a comprehensive solution for identifying both known and hidden mechanical faults in the manufacturing environment.

- Requires minimal training and is easy to incorporate into the maintenance cycle.

- Delivers real-time results for maintenance and repair plans.

The early detection of this fault prevented further damage, as it was addressed before a catastrophic breakdown occurred.