Thermal imaging versatility in the mining industry

Infrared can be a vital monitoring tool during every step of the process

In an industry where adverse weather and environmental conditions are workplace norms for hundreds of thousands of workers, thermal imaging has been proven a dependable tool to help limit unscheduled downtime, improve workplace safety, and in the process, save millions of dollars. This application note explores the value of integrating thermal imagers into “process” condition monitoring (“process” of extracting mineral from the ore) and predictive maintenance programs on electrical and mechanical systems in mining operations. It also touches on newer applications that are becoming more popular in the mining industry.

Challenge

In many ways, a mine site is like a miniature city. It has its own utilities, roads, specialized process equipment, safety standards and regulations, and a dedicated and skilled workforce. Mines operate 24 hours a day, 365 days a year. Extensive infrastructure supplies electric power from on-site substations, moves refrigerated air deep underground, and pumps out water to avoid flooding. Up to 400-ton haul trucks, powerful shovels (gas and electric-powered), crushers, mills and processing facilities extract precious metals, or other essential materials from the ore from miles of underground tunnels or from hundreds of acres of open pit mining.

Mines require extensive power supplies from on-site substations

The Costs of Downtime

A mine's revenue potential correlates directly with its output, which is determined by how well all systems function without unexpected interruption. For example, the Gold Bar project and future mine estimates a production profile of 62,800 ounces of gold per year. Running 365 days a Mines require extensive power supplies from on-site year, that breaks down to a little more than 172 ounces per day and 7.17 ounces per hour. If gold is priced at $1,200 per ounce, then the hourly revenue lost due to downtime is $8,628. At that rate, it takes less than a week for a mine to lose a million dollars. Some mines produce less and some produce much more, and this example doesn't even factor in the increased operating costs also likely to emerge from the breakdown.

Equipment durability and maintenance factor heavily into a mine’s operating cost. Much of the equipment is custom and so specialized that replacing it is cost-prohibitive. And at up to millions of dollars per vehicle, mining companies have to get as much effective use as possible out of its trucks, shovels, and leaching equipment.

Predictive Maintenance Challenges in the Mining Industry

To help avoid catastrophic downtime or equipment loss—and to reduce insurance premiums and improve worker safety—mining companies administer comprehensive predictive maintenance programs to provide uninterruptable power and continuous uptime. The size of the operation determines the size of the teams that administers the programs. But given the complexity of mining operations’ electrical and mechanical systems, these teams require knowledge and training on mining equipment, transportation, and electrical applications. While it’s common for mining companies to outsource some tasks, it’s more cost-effective to keep as much of the monitoring and repair in house. No matter who's executing the PM duties, the mining industry presents some unique challenges to success, including:

- Environmental Conditions: Whether it's due to working at night, underground, in extreme heat or cold, or in wet conditions, most mines offer multiple unique challenges to 24-hour monitoring and maintenance of equipment.

- Dust: Mining, by nature, is a dirty job. But some mines are worse than others. For example, underground coal mines present a larger dust problem than open pit copper or gold mines.

- Going Digital: The mining industry is realizing the benefits of digitizing operations. Like any industry, faster access to data improves cost-efficiency and productivity. They need digital monitoring solutions, which produce data that can inform real-time decision-making that results in a faster return on investment (ROI).

DOWNLOAD Note Here

Solution

More than 20 years ago, Per Fostvedt, founder of Infrared Systems in Ogden, Utah, started promoting thermal imaging to mining operations as a means to improve processing and predictive maintenance programs. “When I first started calling on mines—promoting IR—about 20-plus years ago, the reception was mostly negative. Because at that time, their philosophy was to run equipment to failure, then repair or replace it;’ Fostvedt said.

But the philosophy has changed over the years. Regularly scheduled predictive maintenance programs improve worker safety and save time and money. Thermal imaging cameras have become a vital predictive maintenance tool, most often for electrical and mechanical systems, but also in monitoring many processing and heap leach operations. Worker safety is a major priority in the mining industry. Typically, if there's a solution available that improves safety, then mining companies are willing to invest.

Many mines own thermal imaging cameras and software and send employees to infrared training courses to better understand applications and learn how the IR cameras work. In fact—and this illustrates how the mining industry views the importance of thermal imaging since Fostvedt started Infrared Systems—three thermography certification courses were scheduled and filled by mining companies in 2018 in Elko, Nevada. Due to their success, mining companies in the Southwest U.S. want to continue or possibly accelerate this pace in 2019.

Mining companies also employ specialized outside professionals who must be able collect quality thermal imaging data, gather accurate temperature measurements, and provide timely equipment condition information using heat transfer concepts with both qualitative and quantitative thermography. Contractors must undergo proper Mining Safety and Health Administration (MSHA) certifications, on-site hazard and safety training, and provide background checks. Nevertheless, outside thermography professionals provide expert insight based on proper inspection procedures into identifiable thermal patterns, some of which may take time to manifest.

Electrical ROI

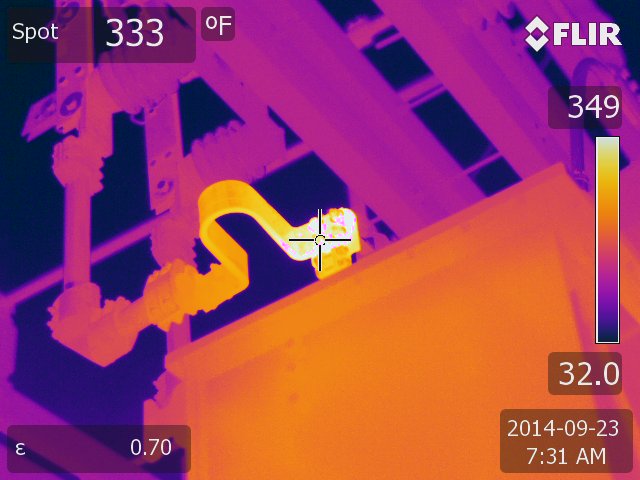

Fig.1 Voltage regulator near failure at a mine station.

Mining operations rely heavily on electric power for ore extraction, transportation, and processing, as it is most efficient and economical and more environmentally friendly than diesel power. Size and voltage levels are generally higher on a mine site compared to most other industries. In fact mining ranked third behind bulk chemical and refining industries in energy consumption in 2017 according to the U.S. Energy Information Administration.

Power is distributed throughout the mine site starting from substations, running through high-voltage transmission lines, then to mobile substations and through transformers. The thermal image in Figure 1 shows a substation voltage regulator termination that is very near failure. This substation fed vital operations, and should it have failed and forced an unplanned shutdown, lost revenue could have reached millions of dollars.

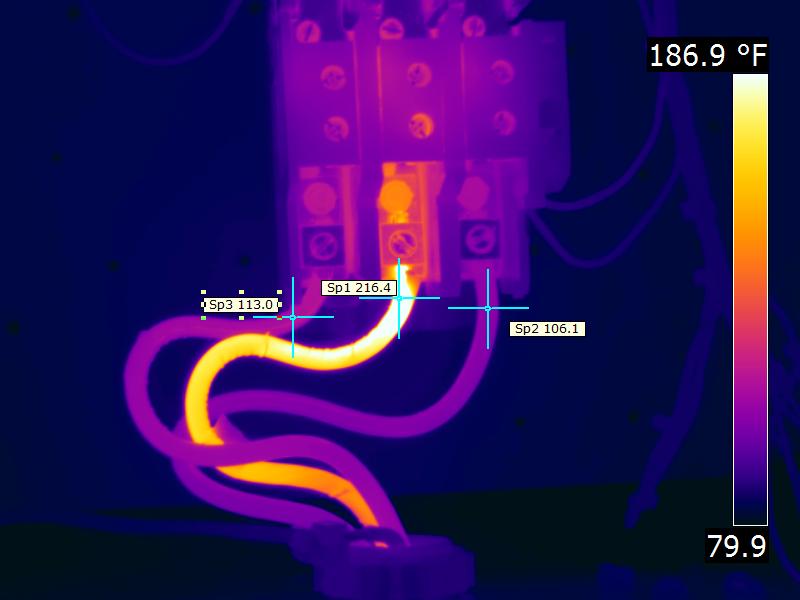

Fig.2 Contractor termination near failure that feeds a VFD processing motor.

Again, in Figure 2, during a contract inspection at another mine site , Fostvedt discovered a 480 V contactor termination in a motor control center (MCC) bucket that was near failure. This MCC bucket fed a variable frequency drive (VFD) motor, the unexpected failure of which could have resulted in lost processing revenues of up to $100K.

Mechanical ROI

According to the Gates Corporation, unplanned downtime at a mine site results in up to $180,000 in lost production per incident. One of the most expensive pieces of equipment that can result in such lost costs is the rope shovel. A rope shovel is the lifeline of any mining operation. If it unexpectedly malfunctions, then consequences ripple through the entire mining process. Most sites don’t have shovel replacement parts readily available. Depending on the issue and age of the shovel, the part may not even be manufactured.

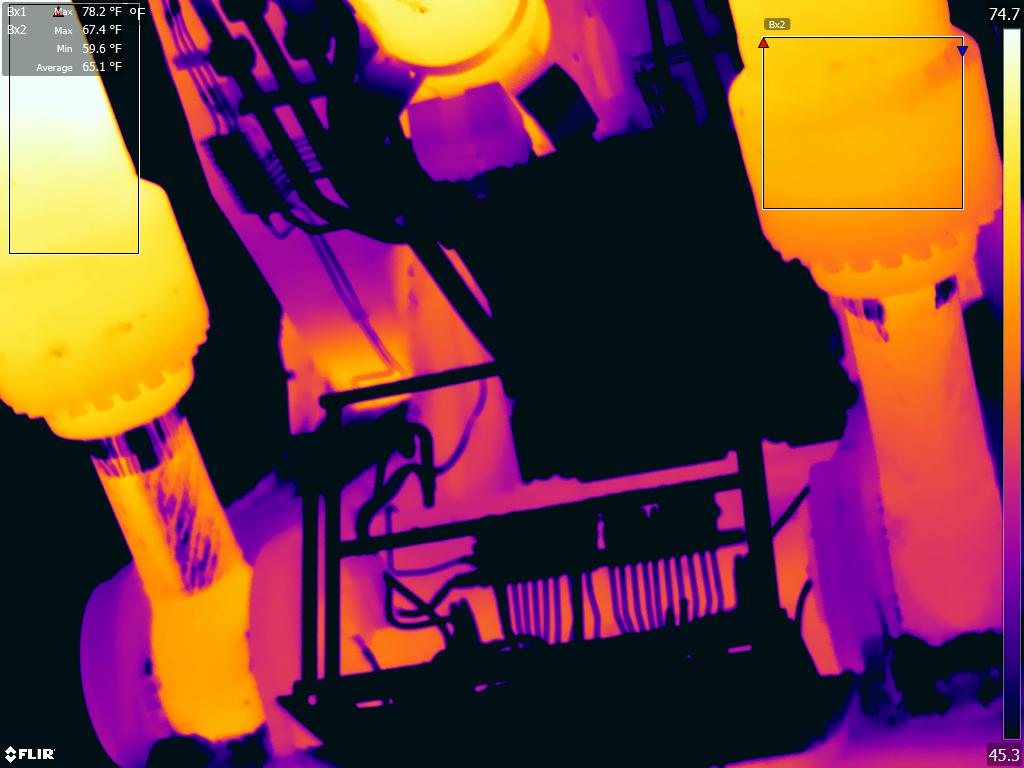

Fig.3 The left boom cylinder on this rope shovel is starting to heat up due to lack of grease.

Downtime can stretch on for days, which is why regularly scheduled maintenance, including IR, is so important. Generally one 12-hour shift per month is allotted to predictive maintenance applications. Issues such as overheating boom cylinders {Figure 3) that can be caught during regularly scheduled maintenance prior to malfunction can mean the difference between a fix during a 12-hour shift or losing $180,000 per hour in production and purchasing a new electric 7200 V rope shovel, which will cost several million dollars.

Other Mining Industry Applications

Thermal imaging applications in the mining industry go beyond electrical and mechanical predictive maintenance. Depending on the type of mine, the following application cases may also be in effect:

- Condition Monitoring. Fix-mounted and vehicle-mounted thermal imaging cameras provide real-time imagery and data to a central monitoring station which tracks everything from temperature gradients to electrical cabinets to switch gear. In mines that are digitizing operations, data from these images can be analyzed over time to more accurately predict failure, schedule shorter maintenance windows, and minimize production downtime.

- Security. Size, accessibility, and safety are factors that can make manual patrols of mining site perimeters challenging. With pan/tilt/zoom configurations of high-definition thermal and color cameras—combined with modern cloud-based networking, software, and analytics—a mine’s command center can monitor the entire site from a single location.

- Safety. By monitoring the integrity of a mine’s walls with thermal imaging, mining companies have more stability data to reference when deciding whether it’s safe to send workers into a mine.

- IR Windows: Many mining operations are requesting that new equipment include IR windows to make thermal imaging inspections safer and easier, especially of electrical equipment. Many mines are undergoing retrofitting of older equipment with IR windows as well.

- Drones: Unmanned aerial monitoring provides a comprehensive perspective of invisible heat differences in electrical transmission systems from the air and for mine site voids.

Helping Mines Stay Productive and Safe

Mining sites require sturdy equipment. Even though thermal imaging cameras see through dust, the accumulation of dust on the lens can put a camera out of commission. FLIR Systems implementation specialists like Infrared Systems use permanent air purging systems to blow dust off the lenses of fixmounted IR cameras. For portable IR cameras, thermographers often conduct inspections with the cameras in sealed, clear plastic bags.

Whatever it takes to get the job done, the mining industry has embraced thermal imaging as a reliable predictive maintenance asset. Fostvedt said, “IR is a vital tool to monitor the transformers that feed watering systems, the refrigeration systems, the processing, MCCs and the substations, surface and underground.”

Thermal imaging is a differentiating technology that helps mining companies do what they need to do to be successful: they have to follow a vein no matter where it goes, and they never know where a core sample might take them.

For more information about FLIR in mining industry applications or to schedule a product demonstration visit www flir.com/applications/industrial