Application Spotlight: Critical Asset Monitoring for Thermal Conditions

The Customer's Challenge

As demand for energy production and high-volume product manufacturing increases, so does the cost of losing production time. Equipment that is crucial to running a process needs to be checked regularly for early indication of distress so that appropriate measures can be taken to avoid failure and allow maintenance crews to plan for downtime.

CONTINUE READING BELOW OR DOWNLOAD THE PDF

THE SOLUTION

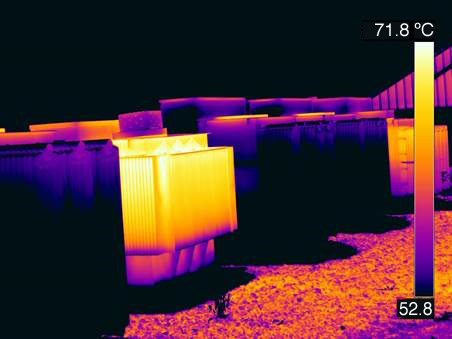

Thermal information from an infrared camera can provide the necessary data to predict and understand when equipment is wearing too quickly or reaching its end of life so that a plan can be put in place for replacement. This is because fixed-mount automation cameras like those made by FLIR can identify slight changes in equipment down to a sensitivity of 30 mK. This level of thermal imaging performance can illustrate subtle changes in the operation of equipment that often display changes in temperature before other indications such as decreased functionality, serious wear, or impending failure occur. FLIR thermal automation solutions also provide the option to report live or record historic temperature profile trends of critical process equipment. They can come equipped with multiple forms of alarming to signal when equipment is failing, seamlessly tying into existing and new control processes to take immediate action when necessary to mitigate problem escalation. The longevity and affordability of FLIR thermal automation solutions can more than offset even a single unplanned outage.

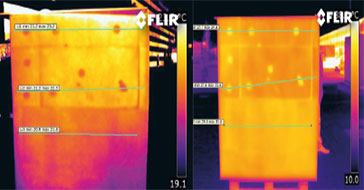

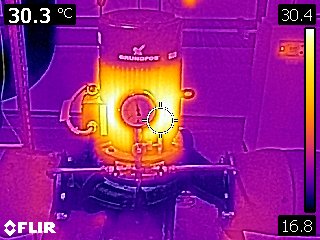

FLIR AX8™ Thermal Imaging Camera for Continuous Monitoring and Safety Monitoring and FLIR A615™ Thermal Machine Vision Camera

FLIR AX8™ Thermal Imaging Camera for Continuous Monitoring and Safety Monitoring and FLIR A615™ Thermal Machine Vision Camera

Pump system monitoring with AX8

THE TECHNOLOGY

FLIR offers a range of fixed-mount thermal smart cameras with built-in software for analysis and alarming. Monitor assets by configuring up to 10 regions of interest (ROIs) using measurement shapes such as spots, boxes, or custom drawn areas in the frame using an easy-to-use web-based configuration window. Set conditions for alarming parameters and the response: data acquisition output type. Uncompromised data is repeatably and reliably generated from thermal detector arrays in either 320 × 240 or 640 × 480 options offering up to ±2°C (±3.6°F) accuracy within temperature ranges of -40°C to 2000°C (-40°F to 3632°F). Integrate FLIR smart cameras into a wide range of control processes using standard communication protocols including RTSP, MQTT, RESTful API, MODBUS TCP & Master, Ethernet IP, and FTP. FLIR thermal smart cameras can be tailored to your application: select manual or automatic focus or change the lens when the field of view needs to be modified. Thanks to its unique compressed radiometric output, these cameras avoid overburdening processors. They also add value to your system by pairing a built-in visual camera and LEDs in partnership with the infrared camera.

FLIR A400/A700™ Thermal Smart Sensor Camera and FLIR A310 IR Temperature Sensor for Critical Equipment Monitoring

HVAC system monitoring

For more information about condition monitoring, please visit: FLIR.com/instruments/condition-monitoring/