Integral UK helps its customers save costs and reduce downtime of chillers.

FLIR GF304 camera ideal solution for detection of refrigerant gas leaks

Chillers commonly use refrigerant gas to provide cooling and therefore temperature control for large commercial properties. Integral is a maintenance specialist, who regularly maintains those assets on behalf of some of the largest clients in Great Britain, many of them household names.

New developments in thermal imaging have enabled Integral to identify refrigerant gas leaks caused by wear or damage, which went undetected by other maintenance methods. The leaks were found quickly and efficiently by the GF304 thermal imaging camera from FLIR Systems.

Integral UK, one of the largest independent providers of property maintenance services in the UK, provides both planned preventative and reactive maintenance to over 1,600 clients in 40,000 locations. The company was a natural partner with FLIR in the development and field trials of the FLIR GF304 camera, which Integral and FLIR believe is a ground breaking product. During its field trial the GF304 has repeatedly demonstrated its effectiveness by identifying refrigerant gas leaks that otherwise went undetected. If left unresolved, the leaks would not only cause long term damage, but would also shorten the life cycle of the asset.

Integral offers a wide range of services, including mechanical and electrical engineering, fabric maintenance, energy and environment services, as well as solutions for fire prevention and protection, security and access controls. Integral employs some 1,300 fully qualified in-house technicians and engineers and has one of the largest national mobile maintenance fleets. The company can rightfully claim to have an engineer in every postcode.

Martin Popowicz, Integral's leading figure in thermal imaging is, an avid promoter of FLIR technology: “We have been using the FLIR thermal imaging camera on major contracts for some time. Some large banking clients have estates that comprise of 400 buildings or more,” he comments. “The cameras helped us save energy, by detecting leaks in buildings that otherwise went undetected, we were able to locate lack of insulation and hotspots. We also used the cameras on the mechanical side, including the maintenance of pumps, motors, compressors, chillers, etc.”

Detection of refrigerant gases

Martin adds: “It has always been difficult to detect refrigerant gas leaks from our chillers. The recent field trial with FLIR however has been most impressive, enabling us to locate and rectify, with greater accuracy and efficiency than ever before, providing clients with early energy savings and far better reliability.”

Integral provided one example where, after a maintenance visit, their subcontractor chiller company told them they had a suspected refrigeration leak. Integral decided to take the FLIR GF304 camera to see if they could locate a leak. The survey was already carried out the next day and quickly and efficiently confirmed there was no leak. This replaced traditional methods where the chiller had to be degased and checked for leaks visually and then recharged – a procedure which could take a week or more. This operation kept the chiller fully operational and Integral was able to avoid the pitfalls of extended downtime. Thanks to these time gains, this saved the client much money, in this case £1200.

Thermal imaging cameras versus gas sniffers

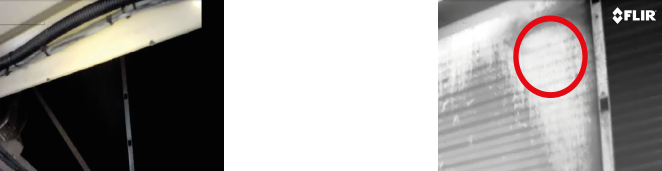

Traditional methods for refrigerant gas leak detection promote the use of sniffers. Unfortunately, because of the way chillers are designed, accessibility is always a problem and you would on average be only able to test 60% of the installation depending on the chiller design and the pipe runs. With the FLIR GF304 thermal imaging camera, access is improved allowing for accurate diagnostics within those areas which are normally difficult to access in normal operations.

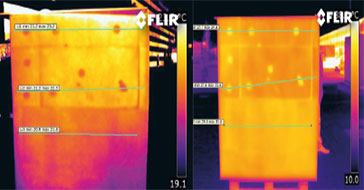

The visual output of the GF304 thermal imaging camera, allows you to clearly see any exit point of the gas, automatically supplying evidence based reports on gas escapes that remain undetectable from any other source.

Reporting: proof for the client

For this reason, FLIR’s reporting software is a valuable communication tool when Integral reports to its clients. The engineer’s report, which also carries a thermal image of the incident, provides the client with a visual representation of the problem allowing him or her to be better informed about the extent and impact of the breakdown.

“Predictive tools like the FLIR GF304 are key to our operation,” comments Martin Popowicz. “If you can identify a gas escape before it develops and apply remedial actions, you can mitigate major failure in the future. This way, you can improve the reliability of the chiller and extend the life cycle of a critical building asset. You can never fully eradicate downtime, but the FLIR GF304 significantly helps to reduce it.”

Dual use

The FLIR GF304 is very versatile and can be used both for finding refrigerant gas leaks and provide the more usual maintenance inspections of high voltage, low voltage, mechanical and general building inspections.

Martin Popowicz: “We most definitely recommend the FLIR GF304 for dual use. For a maintenance company, it is more efficient and provides continued financial benefit. Your employees can carry out a broader range of accurate inspections, during their scheduled maintenance visit. Thanks to the FLIR GF304, an engineer can actually do several tasks with one single camera. Checking the chillers, pumps, motors … pretty much everything. In effect it’s a versatile, cost-effective solution for all our thermal maintenance requirements."