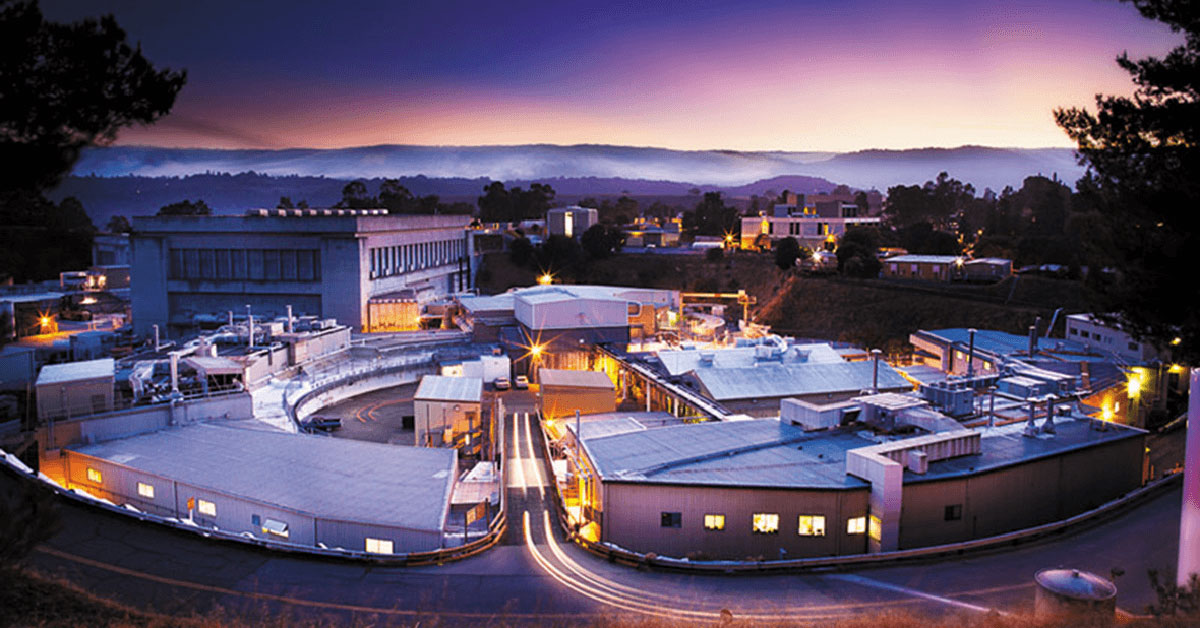

SLAC National Accelerator Laboratory Implements IR Window Solutions

Switchgear Monitoring

SLAC (Stanford Linear Accelerator Center) National Accelerator Laboratory has been helping create the future for more than 50 years. The name SLAC National Accelerator Laboratory pays homage to the legacy of the lab and its connection to Stanford University and the Department of Energy (DOE). Researchers have published hundreds of peer-reviewed papers based on work performed at the lab, leading to Nobel prizes for six scientists.

When SLAC discovered a failed circuit breaker on some very old switchgear, they brought in a consultant to determine the best way to proceed. At the time, SLAC had a preventative maintenance program based on infrared thermography. However, high arc flash incident energy levels on the switchgear, along with the unique construction of the equipment, prevented SLAC’s infrared survey team from accessing the failed equipment. The team might have been able to spot the impending failure in time had they been able to access the load side; instead, the equipment failed without any advance warning.

The consultant worked closely with SLAC’s Predictive Maintenance Group Manager, and determined the optimal solution was the installation of infrared inspection windows.

Final installation of the IR windows

IR windows create a safe barrier between workers and energized equipment, allowing them to survey for hot spots or signs of failure without directly accessing equipment. There were two styles to choose from: round, stainless steel or anodized aluminum windows with broadband crystal lenses, and large, rectangular windows with a polymer optic behind a reinforced grill.

Large format rectangular IR windows provide the largest viewing area available to monitor assets inside energized electrical equipment. Working with SLAC, the consultant determined that the rectangular IR windows were best-suited to the lab’s needs.

SLAC chose to install several IR window sizes, including one 12-inch (304.8 mm) IR window with 9.3 x 5.0 inch (236.2 x 127.0 mm) viewing area and four 24-inch (609.6 mm) IR windows with 20.9 x 5.9 inch (530.9 x 149.9 mm) viewing area. These aluminum-body windows are approved for installation in IP65 / NEMA 4x environments and can withstand temperatures from -40° to 392° F (-40° to 200° C). The polymer optic is UL 746 compliant and permits visual, UV, and IR transmission.

The consultant is now working closely with SLAC to evaluate the potential return on the lab’s investment in the new IR windows. The hope is that by demonstrating a true ROI, this solution can be applied to future projects on other parts of the electrical distribution network at SLAC.

24-inch IR window installed at SLAC

Infrared windows, in conjunction with regular infrared inspections, enable the critical experiments at the laboratory to continue with a reduced risk of unexpected loss of power. Ensuring that experiments at the lab run without interruption should ultimately help further the valuable research being performed there every day.